Non profit

Sugar cane plants as energy self-sufficient

ABB, the leading power and automation technology group, is enabling sugar cane plants throughout Central America become self-sufficient producers of energy and earn substantial revenues by exporting surplus electricity to local power grids.

di Staff

In the past three to four years alone, some 20 sugar cane plants throughout Central America – one of the world’s leading sugar producing regions – have selected an ABB solution which enables them to become self-sufficient producers of energy while simultaneously increasing their revenues by as much as $1 million a year.

The solution uses a highly energy-efficient ABB variable speed drive system – consisting of ACS 1000 medium voltage drives and high-efficiency induction motors – to replace inefficient steam turbines to control the consumption of electrical energy at the cane crushing mills.

One plant alone in Honduras has increased its annual revenues by $1 million, as well as enjoying other bottom-line benefits like rapid return on investment, reduced maintenance costs, higher uptime and improved process operation.

“The overall energy of the plant has increased tremendously since we replaced the steam turbines with ACS 1000 drives. Today, we are not only energy self-sufficient, we have also increased our annual revenues by approximately $1 million by selling excess energy to the grid. Furthermore, the process runs much smoother than before” saidJorge Arriaga, process engineer, Compania Azucarera Hondurena, Honduras.

Sugar plants generate electricity by burning bagasse – the principal waste product after the juice is extracted from the cane – to produce steam for the turbines that run the cane crushing mill.

These turbines operate at low levels of efficiency and they waste steam that could be used to generate more electricity.

By replacing them with high efficiency ABB drive systems to feed power to the cane crushing mill, the steam is used exclusively to generate electricity – enough to meet the needs of the entire plant and provide a large surplus which is sold to the grid.

Higher productivity, lower operating costs

Besides boosting revenues and providing a rapid return on investment, the ABB concept improves plant productivity and the cane-crushing process.

The exceptional speed and torque control of ABB drives enables the mill to operate at constant speed and to start at high torque after a production stop.

Maintenance requirements and noise emissions are negligible.

ABB offers a complete single-vendor solution, ranging from medium voltage drives and robust, high-efficiency induction motors to the power equipment for exporting the surplus energy safely and reliably to the local grid – switchgear, transformers, protection and all auxiliaries.

Case study: http://www04.abb.com/

Find out more: http://www.abb.com/

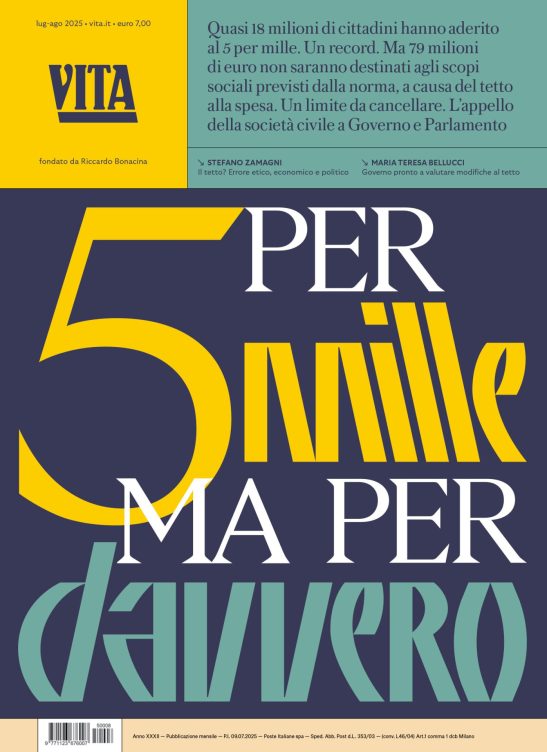

Cosa fa VITA?

Da 30 anni VITA è la testata di riferimento dell’innovazione sociale, dell’attivismo civico e del Terzo settore. Siamo un’impresa sociale senza scopo di lucro: raccontiamo storie, promuoviamo campagne, interpelliamo le imprese, la politica e le istituzioni per promuovere i valori dell’interesse generale e del bene comune. Se riusciamo a farlo è grazie a chi decide di sostenerci.